Sustainability

Rooted in Green, Driven by the Future

Mahacina firmly upholds the development philosophy of “Green Manufacturing, Shared Globally,” integrating its sustainability strategy deeply into product R&D, factory operations, and global partnership systems. We are committed not only to providing customers with low-carbon, eco-friendly, and high-performance coating solutions, but also to embedding environmental responsibility into every aspect of our corporate development.

Environmental Commitment

Mahacina is committed to promoting green processes and environmentally responsible manufacturing worldwide, actively aligning with global policies that advocate low-VOC, non-toxic, and sustainable products. Our coatings are formulated with water-based systems, free of heavy metals, and low in VOCs, reducing potential harm to both the environment and human health through continuous technological innovation.

- All core products comply with major international environmental regulations such as EU REACH, U.S. Green Seal, and China Environmental Labeling (Ten-Ring Certification)

- The entire production process is governed by the ISO14001 Environmental Management System

- Product design prioritizes environmental impact throughout the entire life cycle (LCA)

Circular Economy

We actively promote closed-loop resource management and material reuse, progressively building a green circular economy system:

- Promote the use of recyclable packaging materials to reduce plastic waste

- Optimize production processes to reclaim offcuts and reuse waste liquids

- Encourage customers to adopt centralized material supply and on-demand color mixing for resource-efficient application

- Collaborate with local partners to establish regional raw material recycling stations

Energy Efficiency

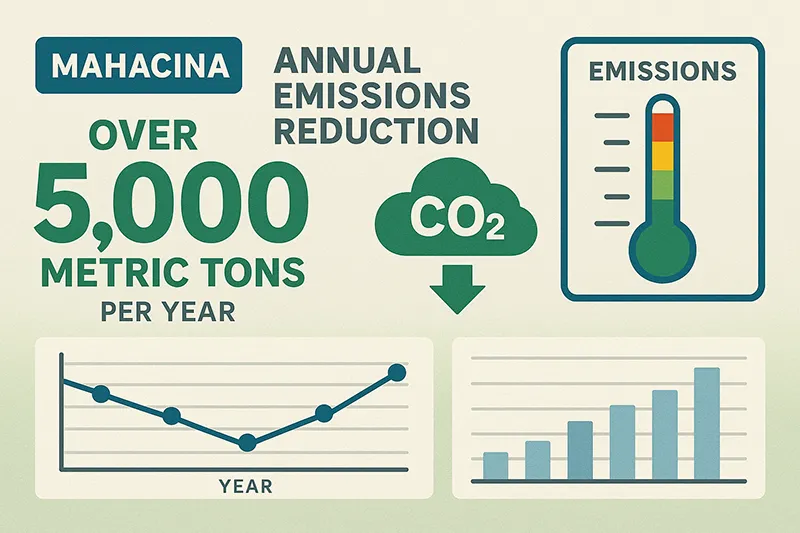

Mahacina continuously reduces energy consumption and carbon footprint through equipment automation upgrades, intelligent management systems, and optimized energy structures:

- Full deployment of intelligent color-matching systems and AI-driven mixing processes has improved energy efficiency by over 40%

- Some factories have already implemented grid-connected solar photovoltaic systems

- Annual CO₂ emissions reduced by over 5,000 tons

- Adoption of low-temperature curing coating technology to reduce energy consumption during application

Green Certifications

We are committed to building a comprehensive green compliance system across our products, factories, and supply chain:

- ISO14001:All global factories are certified under the Environmental Management System

- Low-VOC Coating Certifications (Green Seal / LEED):Multiple water-based coatings are certified by U.S. and EU environmental standards

- Ecolabel:Our eco-friendly building materials meet China’s Green Product Certification requirements

- Green Building Materials Recommended Catalog:Mahacina products have been included in government green procurement lists across various regions

Sustainability Roadmap

| Timeline | Strategic Goal |

| 2025 | 100% of operating factories to complete environmental assessments and compliance upgrades |

| 2026 | Increase the use of green raw materials to 75% |

| 2027 | Achieve ISO14001 + REACH certification across 100% of global factories |

| 2030 | Achieve carbon neutrality at the group level and support franchise factories in reaching the same goal |

| Long-Term | Build a global manufacturing ecosystem integrating “Green Coatings + Green Building Materials + Green Supply Chain” |

Mahacina invites environmentally conscious and socially responsible partners from around the world to join us in advancing green development and building a truly “sustainable, replicable, and profitable” manufacturing system of the future.

To request the Mahacina Annual Sustainability Report or to apply for a green strategic partnership, please contact us.