Transfer of formula technology

- Covering: architectural coatings, floor coatings, anti-corrosion coatings, thermal insulation coatings, water-based wood coatings, waterproof coatings, etc

- Provide mature and validated standard formulas, process parameters, and technical specifications

- Localized adjustments can be made based on customer raw material compatibility

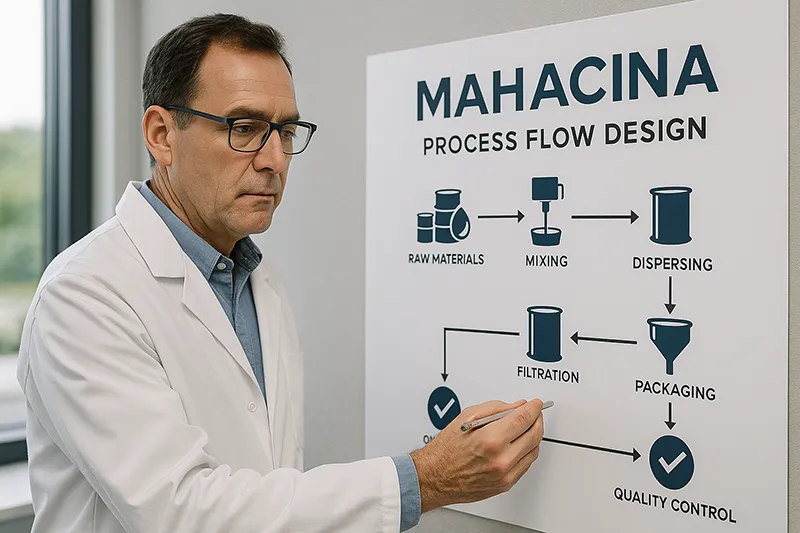

Process flow design

- Guide the standardized production process of dispersion, grinding, color matching, and filling for the entire set

- Layout plan of supporting automation equipment and suggestions for optimizing production line rhythm

- Suggestions for Setting Cleanliness and Safety Standards in Coating Workshops

Raw material technology matching

- Conduct technical evaluation and adaptation plan for available raw materials in the customer’s country

- Can recommend alternative suppliers, raw material data packages, and addition ratios

- Control the consistency of raw materials to ensure batch stability

Laboratory establishment and training

- Laboratory Configuration Plan (Coating Basic Testing/Performance Testing Equipment)

- Standard testing method training: such as viscosity, coverage, adhesion, drying time, etc

- Provide original testing record template+operation SOP

On site technical support

- Engineers can be dispatched to the factory to guide the construction, production, sample verification, and first batch production

- Including the entire process of “line opening verification, sample debugging, quality confirmation, and first order release”

- Suggested cycle: 7-30 days, depending on the complexity of the project

Construction of color matching system

- Build a color paste/color card/color masterbatch matching system to adapt to color mixing machines

- Can support Asian paint, Dulux, RAL, PANTONE systems

- Provide a Color Matching Database

Problem analysis and solutions

- Quality anomaly analysis: delamination, agglomeration, cracking, flow adjustment, etc

- Remote assistance or local sample return for factory testing, issuing technical reports

- Continuously update the ‘Frequently Asked Questions and Answers Manual’

Certification and Regulatory Support

- Assist in preparing MSDS, COA, REACH, ROHS, and environmental testing materials

- Provide reference product technical specification sheet (TDS) and safety instruction sheet (SDS) templates

Product updates and R&D sharing

- 3-5 new product system formulas can be obtained for free every year

- Follow international trends such as water-based, zero VOC, anti-virus, self-cleaning and other technologies

- Collaborative research and development can share achievements according to a franchise system

Systematic intellectual property output

- Use BAYD trademark/logo/label/packaging design template

- Authorize the use of formula copyright, production process know-how, color card visual design, etc

- Clearly define the boundaries and purposes of all intellectual property authorization in the contract